Our Story

Four decades of Flowdrill innovation and technology

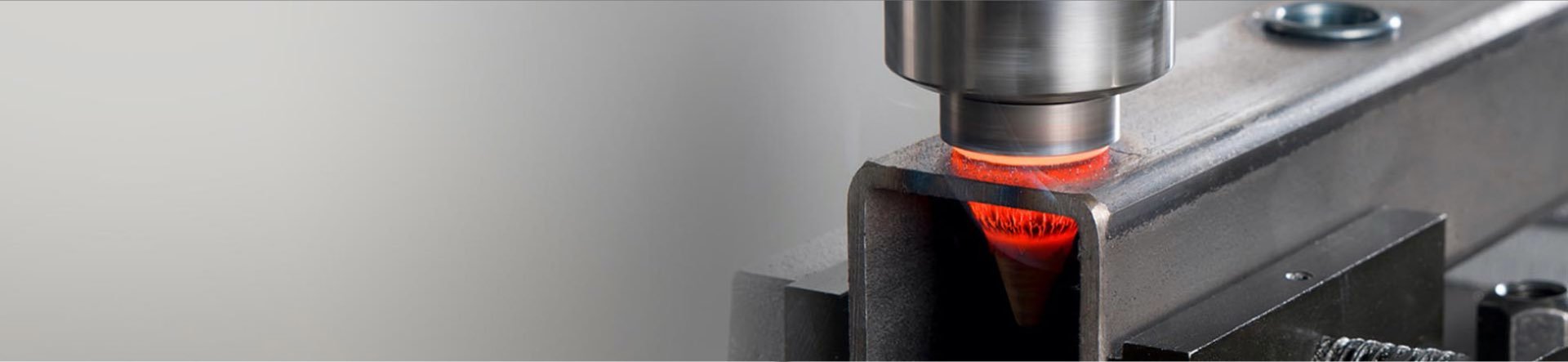

2020 is a milestone year for Flowdrill. It marks four decades since our simple-to-use friction drilling technology was born and started to change the way many of the world’s major industrial sectors achieve stronger and quicker fastening connections by tapping and brazing.

Our unique solid carbide friction drill is now used by over 5000 customers in 50 different countries every year, completing 500 million connections across automotive, furniture production, general fabrication and heating, ventilating and air conditioning (HVAC).

This means automakers can reduce the time it takes to achieve stronger fastening techniques, designers can achieve the required look and feel of their products and modular housing specialists can eliminate costly reworking.

Our approved technology is the visible face of the Flowdrill story. What you rarely see is our state-of-the-art production facility, our R&D team regularly pushing the boundaries of innovation and our close-knit family of application engineers who support customers with installation and ongoing support.

This means we are always there for the client, listening to their challenges and delivering solutions that make them more efficient, helps them save money and improves their speed to market.

There is also a massive environmental benefit. Our carbide friction drills replace 500 million fasteners every twelve months - that’s a massive 2.5million tonnes of steel and, if placed side by side, the fasteners would stretch over 7500 km.

Vision

Flowdrill delivers the connection of choice for tubes and profiles, providing solutions that replace traditional fastening methods, eliminating reworking, improving cycle times, reducing costs, greening your supply chain and improving the aesthetics of your product.

Did you know this about Flowdrill?

Flowdrill technology has been used to help build:

- Components for Weber Gas BBQs

- Key parts for use in F150 Ford Pickups

- McDonalds digital menu boards

- Point of sale retail displays for Tesco

- Office furniture used in the Whitehouse in the United States of America

Did you know?

Using frictional heat to form a hole was first developed in France in 1923. Unfortunately, the right materials and machinery to produce friction drills did not exist until nearly 60 years later when a Dutch engineer developed and commercialised the Flowdrill friction drill.

Our Team

Flowdrill is about much more than our technology and our Friction drills.

Behind the scenes, we have a fantastic team of experts, who are passionate about what we do and how we can help customers save time, improve quality and reduce costs. We also love the fact our products save lots of carbon by replacing thousands and thousands of fasteners every year.

The business is built on strong family principles and this is reflected in the fact that the majority of our global staff have been with us for more than ten years. This gives them significant experience of providing technical support, managing installations and supporting companies with tailored solutions.

Jens Steffen

Menno Haars

Mitch Ray

Nils Hörner

Kitty Schipperen

Passionate about

Sustainability